Custom Assembly Services

From parts to finished goods — precision, reliability, and efficiency in one place.

Fast lead times

ISO 9001:2015, ISO 13485 and AS9100D certified

All uploads are secure and confidential.

Our product assembly service, including manual assembly, automated assembly, and molding assembly, helps global manufacturers simplify supply chains, reduce costs, and accelerate delivery. We combine precision machining, in-house injection molding, and cleanroom assembly to deliver ready-to-use final products. Whether you need small-batch prototyping, large-scale production, or complex multi-component assemblies, our full-service manufacturing solution ensures perfect fit, stable quality, and zero-risk outsourcing.

Why Choose Our Mass Production Assembly Solutions?

Save cost, time, and resources with fully integrated manufacturing and assembly.

01. Cost-Effective Integration

• Single-source production:

Our high in-house manufacturing ratio eliminates the need for multiple suppliers, saving you procurement and management costs.

• No markup layers:

From raw materials to finished goods, all profits remain internal — reducing hidden “transfer costs.

• Optimized logistics:

Ship one complete unit instead of multiple parts, cutting packaging and transportation expenses.

02. Time-Saving Efficiency

• Seamless workflow:

Injection-molded components move directly to our cleanroom assembly line — no storage, no waiting, no delays.

• Unified communication:

One project team handles everything, speeding up decision-making and minimizing communication friction.

03. Zero-Risk Partnership

• Single accountability:

We take full responsibility for product quality — no finger-pointing between suppliers.

• Professional assembly teams:

Trained operators follow standardized procedures for consistent results.

• No capital risk:

You avoid investing in assembly lines or labor management — we handle it all.

Step-by-Step Product Assembly Process

From design validation to final packaging — precision in every stage.

Design Review

We analyze your product design to detect potential assembly challenges early, ensuring seamless production and reduced iteration time.

Component Preparation

Each part undergoes cleaning, deburring, and fit verification to guarantee perfect alignment and compatibility before assembly.

Precision Assembly

Our skilled team executes the assembly using advanced tools and jigs, ensuring accurate alignment, smooth operation, and full functionality.

Packaging & Delivery

After inspection, products are securely packed and delivered in pristine condition — safe, stable, and on time.

Flexible Product Assembly Solutions

Tailor-made for your product type, volume, and budget.

Manual Assembly

Ideal for small-batch, multi-variety, or complex assemblies. Human flexibility allows intricate operations like internal wiring or product prototyping with minimal setup cost.

Automated Assembly

Perfect for high-volume, high-precision production. Using robotic arms and specialized machinery, it ensures speed, accuracy, and long-term cost efficiency for consistent output.

Molding-Assembly Integration

Combines molding and assembly in a single process through overmolding or insert molding. It strengthens part bonding, reduces material use, and eliminates manual assembly — ideal for compact, durable products.

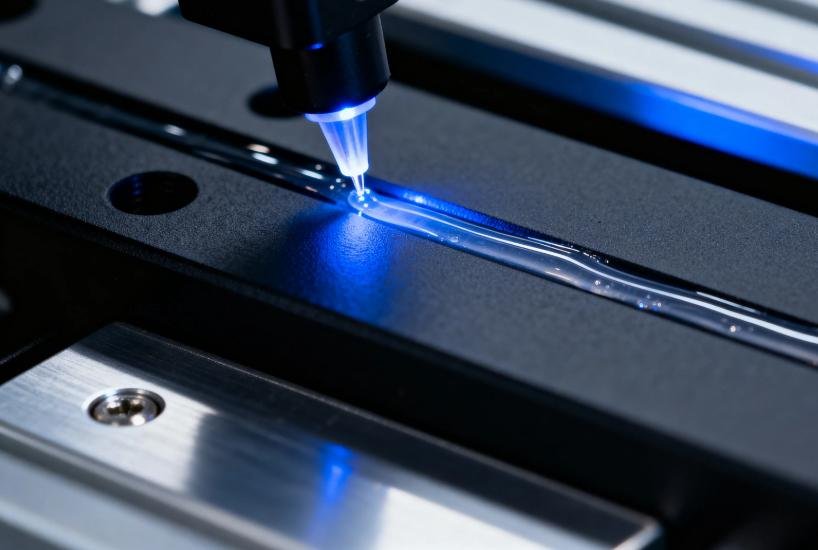

Adhesive Bonding

Utilizes industrial adhesives like UV or AB glue for multi-material joining — suitable for waterproof, dustproof, or optically transparent components such as wearables and sensors.

Ultrasonic & Vibration Welding

High-frequency welding achieves airtight, high-strength plastic joining without glue or screws — ideal for automotive, medical, and waterproof electronics.

Mechanical Fastening

Screws, clips, and rivets allow easy disassembly, strong joints, and visible inspection — best for household appliances and consumer electronics requiring maintenance access.

Your Trusted Turnkey Manufacturing Partner

One supplier. One responsibility. Complete reliability.

Our assembly services integrate engineering design, precision parts production, and quality-controlled assembly into a single streamlined process. With advanced automation, skilled technicians, and strict inspection standards, we guarantee high-yield, high-consistency results for every order.

Get a Quote Today

Simplify your production — partner with us for full-service assembly.

Let us handle the complexity. Contact our engineering team to discuss your design, and we’ll build your next product from concept to completion — faster, cheaper, and better.