Rapid Manufacturing for High Quality Plastic Parts

Rapid Manufacturing for Plastic 3D Printing Solutions

In today’s fast-paced product development world, plastic rapid manufacturing, plastic 3D printing manufacturing, and plastic prototype to production have become essential for innovators seeking speed, precision, and cost-efficiency. Through plastic additive manufacturing parts and plastic small-batch production 3D, businesses can achieve plastic on-demand manufacturing with faster delivery and lower investment risk. Whether you need plastic customized parts 3D printing or plastic efficient 3D printing manufacturing, our all-in-one rapid manufacturing solution ensures quality, speed, and scalability.

Comprehensive Plastic Rapid Manufacturing Services — From Prototype to Production

We offer an integrated plastic 3D printed production parts service platform that covers every stage from idea to finished product. Each process is optimized for plastic low-volume production 3D printing and plastic cost-effective 3D printing manufacturing, ensuring flexible and rapid turnaround.

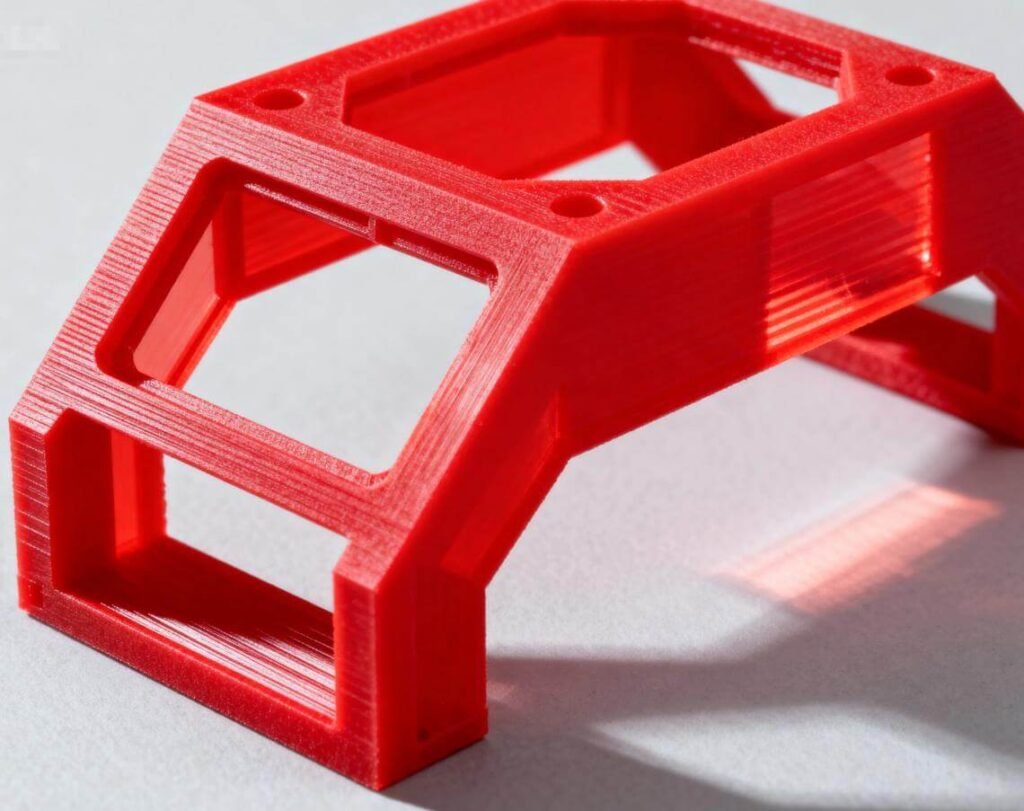

3D Printing — The Fastest Plastic Prototype Manufacturing

Plastic rapid production technology is ideal for design validation and concept testing. Our plastic production 3D printing enables you to transform digital models into real parts within hours.

• Advantages: No tooling, complex structure freedom, cost-effective

• Applications: Concept models, design iteration, and small-scale customized production

This process allows plastic functional parts 3D printing manufacturing for visual models, prototypes, or final-use components.

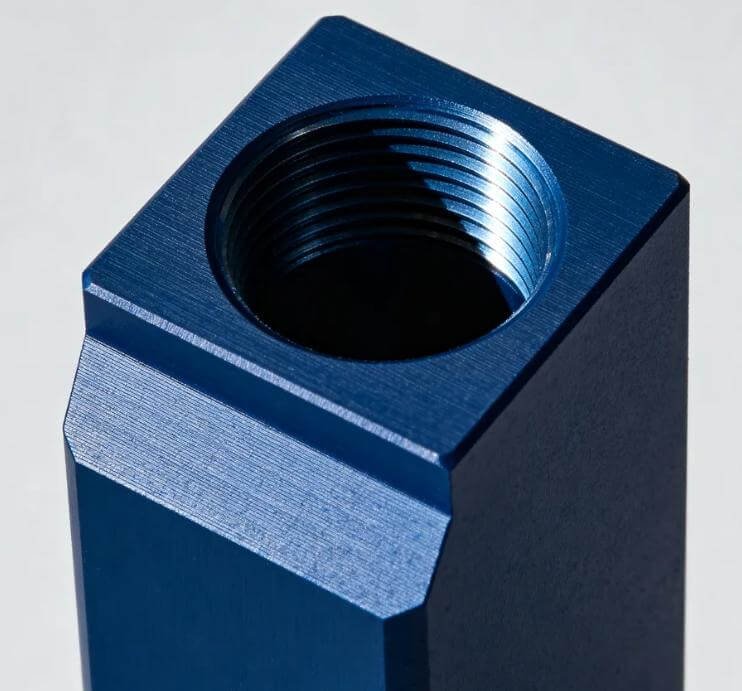

CNC Machining – The High-Precision Functional Choice

Key Advantages:

Offers a wide range of materials (both plastics and metals), delivers exceptionally high precision comparable to mass production, and provides superior strength—ideal for functional end-use parts.

Applications:

High-Precision Functional Prototypes: Suitable for components requiring real load-bearing or assembly testing.

Metal Part Sampling: Used for producing high-strength and heat-resistant metal prototypes.

Low-Volume Production: Ideal for small batches (tens to hundreds of pieces) where material performance and dimensional accuracy are critical.

Rapid Tooling — Plastic Small-Batch Manufacturing Made Simple

Plastic rapid manufacturing service with plastic rapid tooling shortens the transition from prototype to pilot run.

• Advantages: Production-grade materials, fast lead time (2–4 weeks), low mold cost

• Applications: Market testing, clinical trials, and limited pre-production runs

This approach bridges the gap between plastic 3D printed production parts and full-scale manufacturing.

Vacuum Casting — High-Quality Plastic Parts Replication

hen visual quality and material feel matter, plastic manufacturing with 3D printing combined with vacuum casting delivers exceptional results.

• Advantages: Superior surface finish, diverse materials (soft, transparent, colored plastics)

• Applications: Show models, demo units, multi-material production

It’s the go-to choice for plastic large-scale 3D printed manufacturing in presentation and user-testing environments.

What Is Plastic Rapid Prototyping?

Plastic manufacturing innovation 3D printing transforms your concept into tangible form quickly and efficiently.

By leveraging plastic high-speed 3D printing manufacturing, early-stage designs can be validated within 1–3 working days.

This process reduces financial risk while ensuring functional testing accuracy.

Plastic digital manufacturing service empowers brands to accelerate product iteration and optimize engineering design before mass production.

How to Choose the Right Plastic Rapid Manufacturing Process

Comparison of Four Rapid Manufacturing Solutions

| Solution | Key Advantages | Main Limitations | Ideal Application Scenarios |

|---|---|---|---|

| 3D Printing | • Fastest turnaround time • No tooling required • Handles complex geometries easily | • Lower strength compared to molded parts • Visible layer lines on surface • Limited material options | • 1–50 pcs • Concept models, appearance validation, complex design iterations |

| CNC Machining | • Best material performance • High precision and strength • Wide material availability | • Higher relative cost • Limited for complex internal structures • Some geometric restrictions | • 1–100 pcs • High-precision functional testing, assembly verification |

| Rapid Tooling | • True production-grade process • Lowest cost per unit • Material identical to final production | • Requires mold fabrication • Higher upfront cost • Expensive to modify design | • 100–5000 pcs • Small-batch pilot production, market validation, crowdfunding fulfillment |

| Vacuum Casting | • High-quality small-batch replication • Excellent appearance and tactile feel • Compatible with soft or transparent materials | • Requires master model • Limited mold lifespan (tens of cycles) • Alternative resin materials only | • 10–100 pcs • Display prototypes, multi-material small-batch runs, user experience testing |